Pair Matching (Duplexing)

At Silverthin, we excel in the science of pair matching ensuring optimized performance. Our approach to pair matching is rooted in precision:

- Selection: We initiate by choosing bearings that are inherently complementary, ensuring a strong foundation.

- Precision Matching: Employing advanced tools and techniques, our experts match the bearings to achieve optimal alignment and synchronization.

- Testing: Every matched pair undergoes rigorous testing to validate its performance, alignment, and overall harmony.

Why it Matters

- Enhanced Load Handling: Duplexed bearings can handle increased and bi-directional loads, offering superior rigidity.

- Reduced Operating Deflection: Synchronized bearings ensure smoother operations, reducing deflections and vibrations.

- Optimized Precision: When precision is paramount, duplexed bearings ensure the tightest alignment and synchronization.

Silverthin Advantage

- Versatility: Whether it’s for high-speed applications, precision instruments, or demanding environments, our duplexed bearings rise to the challenge.

- Consistency: We ensure that each bearing pair is consistently matched, guaranteeing reliable performance batch after batch.

- Extended Lifespan: Optimized alignment reduces uneven wear and tear, leading to extended operational life.

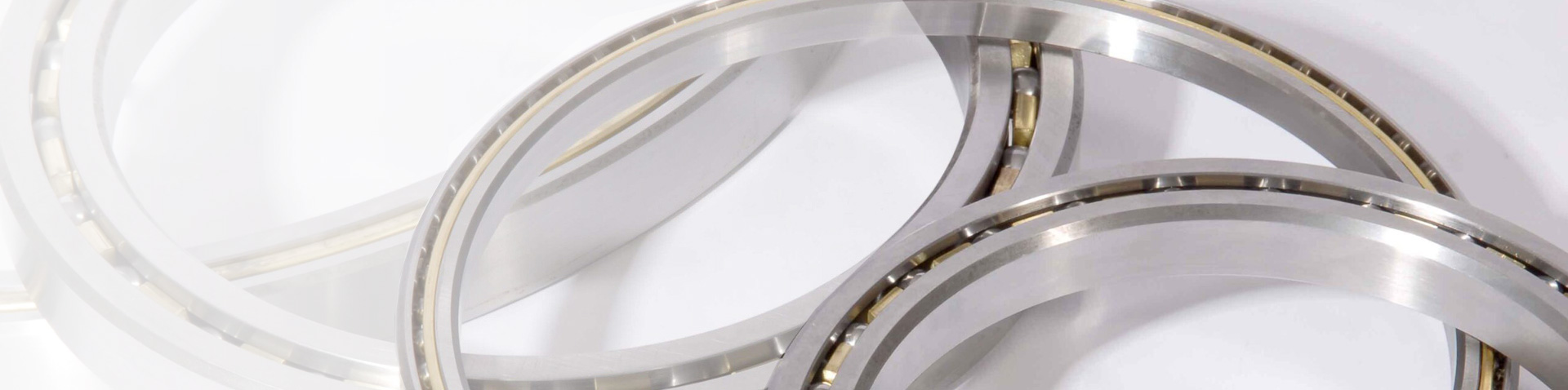

Duplexing of Silverthin Thin Section Bearings

Silverthin Type-A Angular Contact Ball Bearings can be used as single, unmatched bearings. However the overwhelming majority of applications require them the be Duplexed, or Pair Matched (other common terms are Matched Pairs or Matched Sets). The bearing faces are configured in such a way that they can be mounted together to yield a fixed preload. or clearance condition. Note that duplexed bearings can consist of more than 2 bearings, such as a Triplex or Quadplex.

Load carrying capability for Duplex Bearings is as follows:

- Radial Capacity for matched bearings is the single bearing radial capacity times N*0.7, where N is the number of bearings.

- Thrust Capacity for matched bearings is the single direction thrust capacity times N*0.7.

The purpose of Duplexing bearings is to:

- Achieve stiffness, deflection, movement or vibrational performance characteristics.

- Achieve life goals.

- Achieve frictional moment (torque) performance characteristics.

- Accommodate wide and/or extreme temperature ranges

- Accommodate dissimilar mating component material

- Accommodate reversing thrust and/or moment loading

|

|

|

|

Markings and Orientation

Note that single angular contact ball bearings can only accommodate thrust in one direction. The outer diameter of these bearings is marked with an arrow and the word ‘Thrust’ to indicated the direction thrust load may be applied. In a Back-to-Back (B) arrangement, these arrows will point away from each other. In a Face-to-Face (F) arrangement, these arrows will point toward each other.

Angular contact bearings purchased as Duplexed Pairs will have a ‘V’ marking on the OD and ID of the bearing. When the V’s are aligned with each other during installation, they are properly oriented. They also represent the location of the high point of radial runout for the duplexed pair. This high point can be aligned with the low point of runout on the mating shaft and housing to reduce overall runout of the assembly.