Specialty Coated Bearings

Bearing Coatings

Coatings for Silverthin Thin-Section Bearings are available and generally serve one or both of two purposes: corrosion resistance and protection, and lubrication. For a discussion of lubrication, please refer to the Lubrication section of the website and catalog. This section will address corrosion resistance and protection.

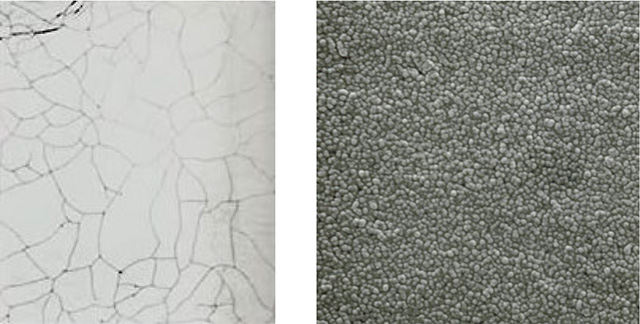

Nodular Thin Dense Chrome (NTDC) coating options are available by Silverthin for corrosion resistance whenever 440C Stainless Steel material may not be practical. NTDC coating adheres to the base metal of a standard Silverthin 52100 Steel bearing via electro-deposited chrome plating and does not chip, crack or peel under severe stress.

NTDC coating offers a uniform coating thickness of approximately 0.0002” and the following characteristics:

- Hardness up to 78 HRC

- Corrosion resistance generally equivalent to 440C Stainless Steel

- FDA Compliance and a blanket food safety approval from the USDA

For torque critical sensitive applications, NTDC coating may not be advisable, and users should consider using 440C Stainless Steel for corrosion resistance and protection.

NTDC coating excels in applications such as shipboard or coastal saltwater exposure and can be applicable for environments with caustic chemicals or gases.

Please contact Silverthin Engineering for application review and product suitability.

Common Hard Chrome coating (left) is prone to microcracking under stress while NTDC coating (right) microstructure is more resilient to stress.