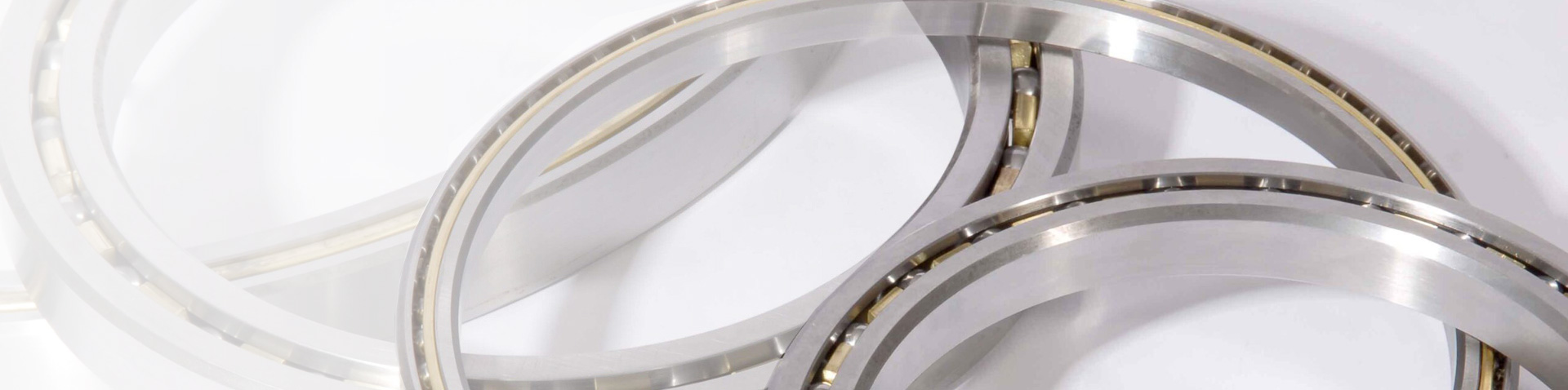

Bearing Analysis/Application Analysis

Why Bearing Analysis Matters

Every application places unique demands on bearings. An incorrect match or a bearing operating sub-optimally can lead to:

- Reduced Equipment Lifespan: Accelerated wear and tear can occur.

- Increased Downtime: Frequent maintenance breaks can disrupt operations.

- Elevated Operational Costs: Replacements and repairs can add up.

Bearing & Application Analysis

We don’t just look at bearings; we look at how they integrate with their environment:

- For the Aerospace Industry: In the vast expanse of space, there’s no room for errors. We analyze bearings ensuring they can bear the extreme conditions and function seamlessly.

- In Medical Equipment: A millimeter can make all the difference. Our analysis ensures that bearings meet the high precision and reliability standards.

- For Robotics & Automation: Efficiency is key. We analyze bearing performance in real-time operations, ensuring they meet the speed and resilience the industry demands.

Comprehensive Application Analysis

Our Application Analysis evaluates:

- Operational Conditions: Evaluating temperature, speed, and load factors.

- Lifecycle Expectations: Determining the expected operational lifespan to ensure the bearing matches the application’s needs.

- Integration Challenges: Assessing potential challenges when integrating the bearing with your machinery or system.