Rotation & Movement

Oscillating, Intermittent and Dithering Rotation and Movement

While Silverthin Thin Section Bearings are used in an endless assortment of applications and performance criteria, it is very common to see applications where constant, single-direction movement is either not present or only describes a portion of the performance expectation. This type of rotation and movement presents its own set of considerations such as lubrication, life, loading and contact stress evaluation.

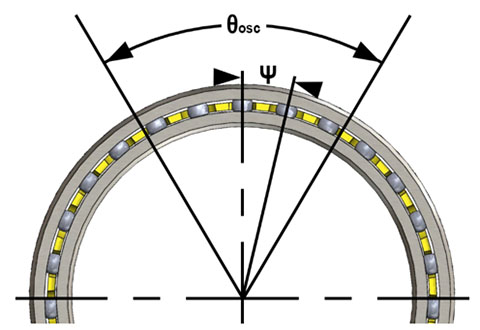

Oscillating, or oscillatory, motion or rotation is the most straightforward to quantify and analyze. In the figure below, the Angle of Oscillation, θosc, represents the boundaries of the oscillating movement. It is recommended that θosc be at least 1.5X the ball spacing angle (Ψ) to limit the chance for false brinelling.

Note that the equivalent speed for oscillation, nosc, can be calculated as follows:

n=nosc*(Ψ/(180°))

Intermittent Rotation is rotation not necessarily of a constant direction, oscillation angle, or speed. This type of rotation is also often referred to as Dithering. All three of the variables noted above can be in a constant state of change or stasis.

For intermittent rotation it is often difficult or impossible to determine an accurate L10 life, therefore other parameters relating to performance are often evaluated, such as:

Starting Torque (Mfriction). In this case there is typically a maximum allowable torque contributed by the bearings allowed.

Viscous Torque (Mv). The torque contributor is difficult to calculate with reasonable accuracy, so it is best to determine this value by testing. Certain lubricants are familiar within industries and applications and some generic conclusions as to acceptability can be drawn from experience.

Static Safety Factor (SF). Typically, it is desirable to have this value be greater than 1.00. A deeper review of contact stress is often helpful in evaluating this parameter.

Contact Stress (pmax, pmin, pavg). Many times, contact stress is evaluated to make sure it is not too high, pmax.

Contact Silverthin Engineering directly for detailed assistance and recommendations for your application.