Wait a Moment!

Thin Section Bearing Moment Load Considerations

Preston, WA (SilverThin eNews) April 2013

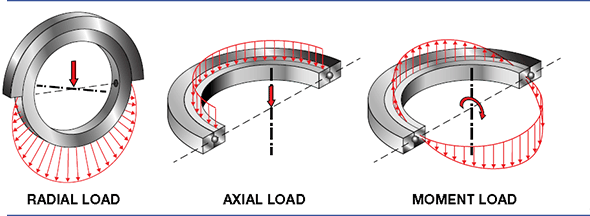

What is a moment load? A moment load is a tilting load that attempts to rotate the rings of a rolling element bearing in a rotational manner perpendicular to the designed rotational axis. Single ball bearings aren't usually designed to handle moment loads, but Silverthin offers engineered solutions for space and weight limited applications.

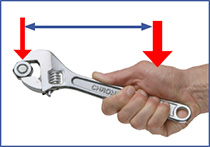

To further explain, a moment load may also be thought of as a "torque". A

"moment", or "torque", is a force (or load) acting at a specified distance from

a

specified point. For example, when you tighten a bolt using a wrench, the

resulting "moment" is the product of the amount of actual force you exert on

the wrench multiplied by the distance from the center of the bolt to the

position of your hand on the wrench. In the case of a bearing, a moment load

is a multiple of the distance from the center of the bearing and the force

acting on an arm.

specified point. For example, when you tighten a bolt using a wrench, the

resulting "moment" is the product of the amount of actual force you exert on

the wrench multiplied by the distance from the center of the bolt to the

position of your hand on the wrench. In the case of a bearing, a moment load

is a multiple of the distance from the center of the bearing and the force

acting on an arm.

Most designers are familiar with bearing applications having multiple bearings (2 or more) that work together to accommodate the loading in the system. The resulting bearing loads in these cases are typically analyzed as radial or thrust loads when evaluating the bearing system. However, by only having a single bearing, any radial load in a system acting anywhere other than at the center of the bearing ball path will generate a moment load. SilverThin offers bearings from stock that are specifically designed for applications with significant moment loads, where there are space, weight and cost saving benefits of using a single bearing. These are unique and specially designed single row, thin-section ball bearings where the internal geometry of the race is reminiscent of a gothic arch, also known as an X-Type bearing design.

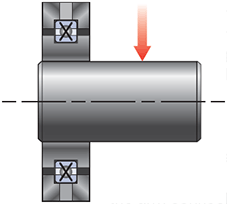

When only one bearing is in a system, as is also the case in

many slewing ring bearing applications, any load can

generate significant moment load. Large moment

loads often occur when an apparatus extends from

a platform with a slewing ring or thin section

bearing at its base. A simple example might be

that of a robotic arm extending a few feet from a

stationary base to pick a heavy object and turn it.

The thin-section or slewing ring bearing at the base of

the arm connecting it to the platform experiences a moment load.

When only one bearing is in a system, as is also the case in

many slewing ring bearing applications, any load can

generate significant moment load. Large moment

loads often occur when an apparatus extends from

a platform with a slewing ring or thin section

bearing at its base. A simple example might be

that of a robotic arm extending a few feet from a

stationary base to pick a heavy object and turn it.

The thin-section or slewing ring bearing at the base of

the arm connecting it to the platform experiences a moment load.

When a bearing is constantly or intermittently loaded, it should be engineered to

handle the life requirements of the application. It is important to identify as much of

the potential loading that a bearing system could face at the design stage in order assure the

complete system will meet its users' service requirements. If you have a

thin section or slewing ring bearing application, contact SilverThin's sales engineers

for help in finding the best solution. https://www.silverthin.com/contact/

complete system will meet its users' service requirements. If you have a

thin section or slewing ring bearing application, contact SilverThin's sales engineers

for help in finding the best solution. https://www.silverthin.com/contact/

SilverThin offers a wide range of X-Type bearings designed to accommodate moment loading in a variety of applications. Many sizes are available from SilverThin stock or from their distribution network. For more information on these bearings and a product selector by click here. https://www.silverthin.com/products/thin-section-bearings/selection-guide/

Contact Information

Scott Shupp

Silverthin National Sales Manager

scott.shupp@mechatronics.com