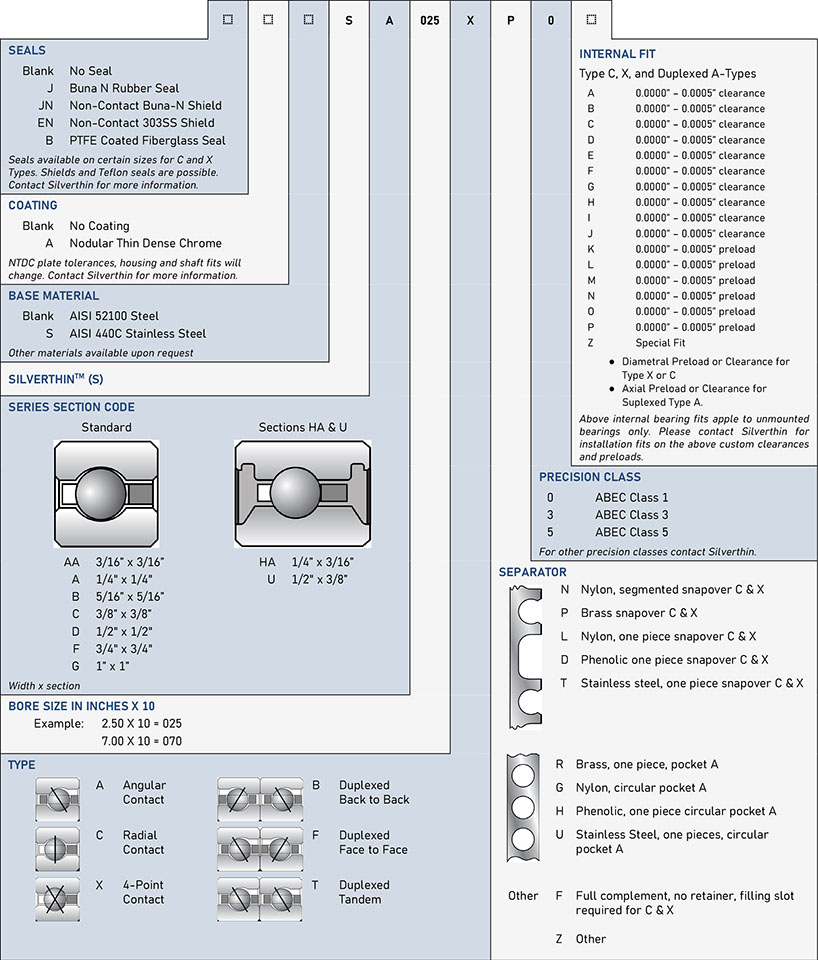

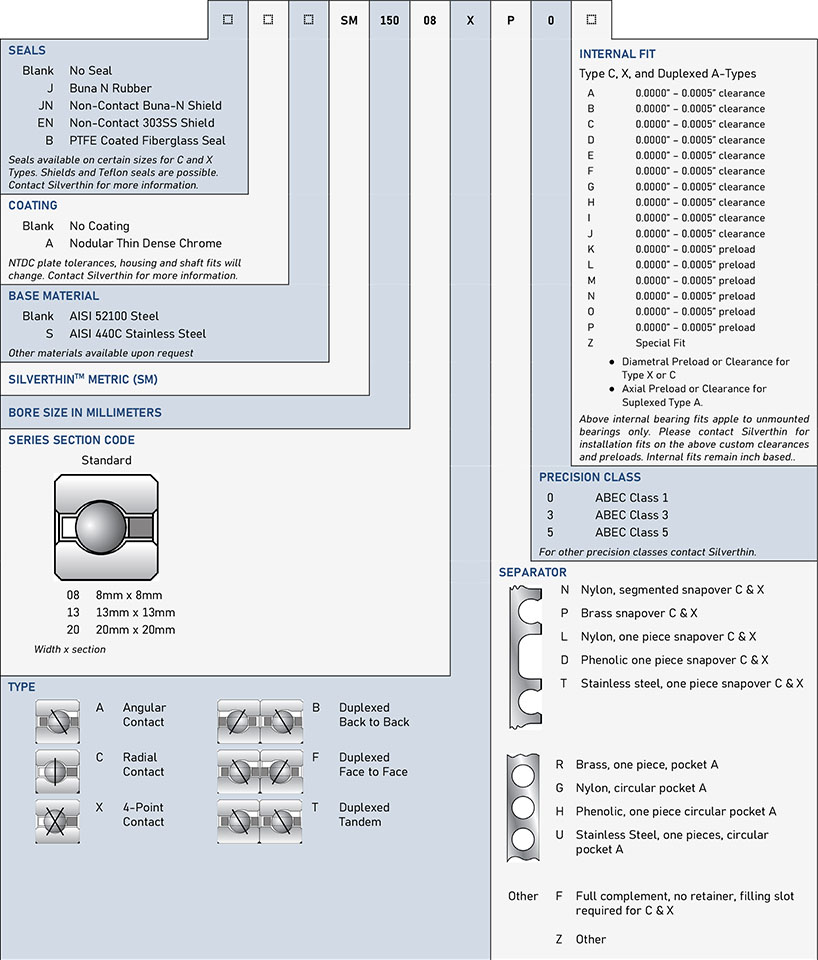

Part Number System & Options

INCH SERIES

METRIC SERIES

Seals and Shields

To maximize bearing life it is important to ensure bearings remain clean and well lubricated throughout their lifespan. Seals and shields assist in these functions and are readily available on certain bearing cross sections and bore diameters. See the Silverthin Sealed Bearing dimension tables for commonly available sizes.

Seals are fabricated with Buna-N Rubber with a metal backing to aid in installation. Seals are retained within the outer ring and and make positive contact along the inner ring. As with all sealed bearings there is an expected slight increase in torque due to the positive contact. All sealed bearings will ship with grease, and a custom grease fill is possible if desired.

Shields can be fabricated from either a Buna-N Rubber with a metal backing or from 304 Stainless Steel. Shields are retrained within the outer ring and floats over a groove within the inner ring. Unlike seals, shields do not come with an increase in running torque and are ideal for high speed or torque sensitive applications.

Contact Silverthin Engineering for seal and shield information and availability. Custom seals and shields are possible with Engineering review and added lead time.

Stainless Steel Bearings (AISI 440C)

Standard base material for Silverthin Thin Section Bearings is the industry standard AISI 52100 Bearing Steel. For applications where the bearing is exposed to corrosive environments Silverthin offers a AISI 440C Stainless Steel as the base material. AISI 440C Stainless Steel offers better resistance to corrosion and is available for each bearing type (Type A, C and X) and both in open and sealed configurations.

Overall dimensions and capabilities of AISI 440C Stainless Steel Bearings are identical to those of AISI 52100 Bearing Steel, and same dimension tables can be used for either bearing material. Contact Silverthin Engineering for bearing material recommendations, or for inquiries regarding non-standard bearing materials.

Bearing Coatings

Coatings for Silverthin Thin-Section Bearings are available and generally serve one or both of two purposes: corrosion resistance and protection, and lubrication. For a discussion of lubrication, please refer to the Lubrication section of the website and catalog. This section will address corrosion resistance and protection.

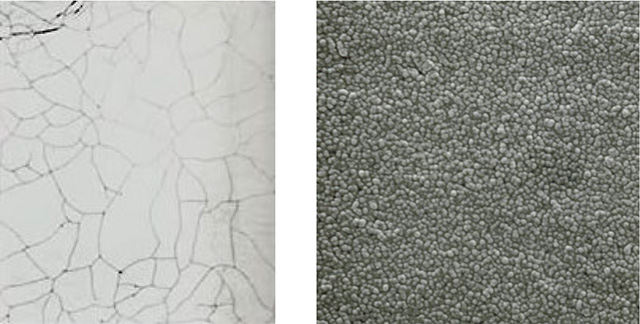

Nodular Thin Dense Chrome (NTDC) coating options are available by Silverthin for corrosion resistance whenever 440C Stainless Steel material may not be practical. NTDC coating adheres to the base metal of a standard Silverthin 52100 Steel bearing via electro-deposited chrome plating and does not chip, crack or peel under severe stress.

NTDC coating offers a uniform coating thickness of approximately 0.0002” and the following characteristics:

- Hardness up to 78 HRC

- Corrosion resistance generally equivalent to 440C Stainless Steel

- FDA Compliance and a blanket food safety approval from the USDA

For torque sensitive applications, NTDC coating may not be advisable, and users should consider using 440C Stainless Steel for corrosion resistance and protection.

NTDC coating excels in applications such as shipboard or coastal saltwater exposure and can be applicable for environments with caustic chemicals or gases.

Please contact Silverthin Engineering for application review and product suitability.

Common Hard Chrome coating (left) is prone to microcracking under stress while NTDC coating (right) microstructure is more resilient to stress.

Hybrid Bearings (Ceramic Balls)

In high speed applications where low torque is a requirement, the running torque can be lowered further with the use of ceramic balls. Silverthin hybrid bearings with ceramic balls replaces the standard AISI 52100 Steel balls or AISI 440C Stainless Steel balls with silicon nitride (Si3N4) balls. Hybrid bearings typically have torque reduction, operation at higher speeds, smaller lubrication needs, reduction in adhesive wear, and overall less heat generation.

Instudry standard Static and Dynamic Load Ratings should be reduced by roughly 30% compared to the load ratigns found in catalogs and datasheets. The Silverthin Datasheet Generator also accept hybrid bearing part numbers and will auto-correct load ratings. Add code “-B01” to the end of any Silverthin Datasheet part number to convert it to a hybrid bearing with ceramic balls.

Contact Silverthin Engineering for hybrid bearing application review or for access to the Silverthin Datasheet Generator.

SuperDuplex Then Section Bearings

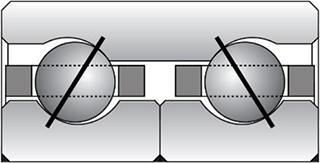

If you need a Duplex Pair of Silverthin Thin Section Bearings, you may want to consider a SuperDuplex design.

This design provides the exact same technical specifications of a Duplex Pair of Silverthin Type-A (angular contact) bearings, except with a 1-piece outer ring. One of the primary advantages to this design is for ease of assembly into your application. In this case there is no option to space the bearings apart. However, since the two rows of balls share a common outer ring and make up a single assembly, there is no possibility to install the bearing thrust (axial) load orientation improperly. It also may save in assembly time and improved mating component design simplicity. Should greater spacing between the two rows of balls be desired, contact Silverthin Engineering to determine if matched ground spacers from Silverthin are appropriate for your application design and assembly.

Silverthin SuperDuplex Thin Section Bearings come from the factory with your Preload or Clearance specification built in. By clamping the inner rings together, these specifications are achieved.

Refer to the catalog for dimensional tables and part number explanation. It is recommended that Silverthin Engineering be consulted by any designer wanting to use Silverthin SuperDuplex Thin Section bearings.

Extra Thin Section Bearings

While Silverthin is the premier source for Made in the USA Thin Section Bearings, sometimes they are just not thin enough. Some applications require even lighter, thinner bearings. In those cases Silverthin Extra Thin Section Bearings represent a unique option. All of these parts are made in the same internal design configurations as Silverthin Thin Section bearings, and all are Made in the USA:

- A-Type (Angular Contact – 30°)

- C-Type (Radial)

- X-Type (Four Point Contact – 30°)

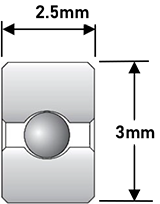

Aside from being Extra Thin, the cross-sections are not square. They come in one constant cross-section:

- 2.5mm Wide x 3mm High

These bearings provide a unique solution for small spaces and provide less torque than more common bushing or plain bearings that may be used. It is recommended that Silverthin Engineering be consulted by any designer wanting to use Silverthin Extra Thin Section bearings. Their unique geometry requires extra considerations.

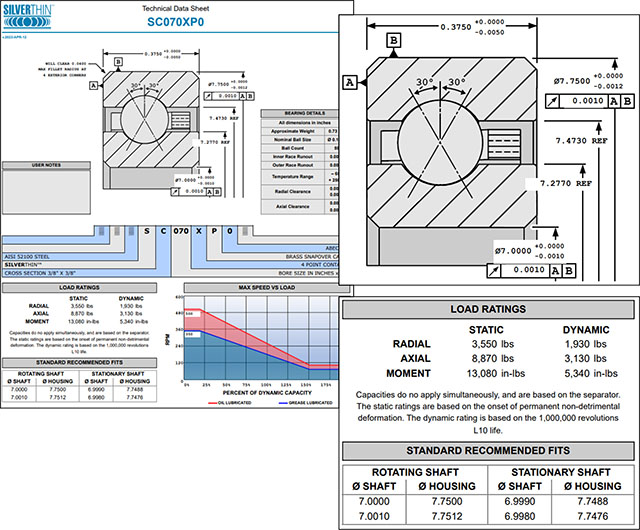

Silverthin Datasheet Generator

The Silverthin Datasheet Generator is a useful reference for bearing dimensional information, loading capacities, speed ratings and mating component dimensional guidelines. Generate a custom datasheet specific to any part number with any combinations of options or modifications.

Please contact Silverthin for access to the Silverthin Datasheet Generator.

Datasheet information includes:

- Part numbering system breakdown

- Support for standard inch and metric part numbers

- Dimensions and tolerances

- Static and Dynamic Load Ratings

- Speed Ratings and Grease Calculations

- Recommended Fits table for mating parts

Additional Features:

- Switch between Imperial and Metric units easily

- Translation support between 10+ languages

- 3D model download support

- Competitor part number recognition